CSG Exploration and Production Services has launched several products and innovations, which features an extended support in mining industry for cost-effective and efficient operations.

Introducing a new products into the market is a significant business achievements for CSG-EPS. Mining product innovation ideas allows us to proactively review customer opinion and unlock insights about new functionality and features that the market expects, in order to gain a competitive advantage.

CSG-EPS provides know-how and resources to support clients from the early exploration stages through to the production phase and developments. Energy Industry clients are able to benefit from the specialist technical expertise and valuable hands-on technical experience brought by us.

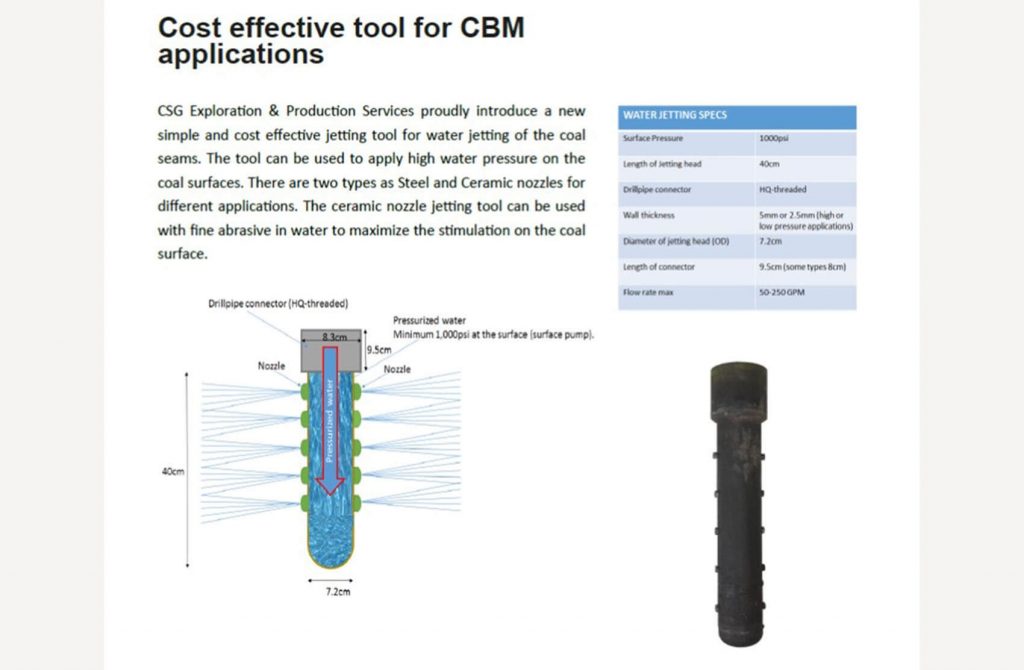

WATER JET TOOL: CSG-EPS’s water jet system was introduced to drilling industry for cost-effective, fast well bore cleaning water fracturing of the coal formations to increase the gas flow. The system was fully developed by CSG-EPS in-house capabilities and used successfully in drilling operations.

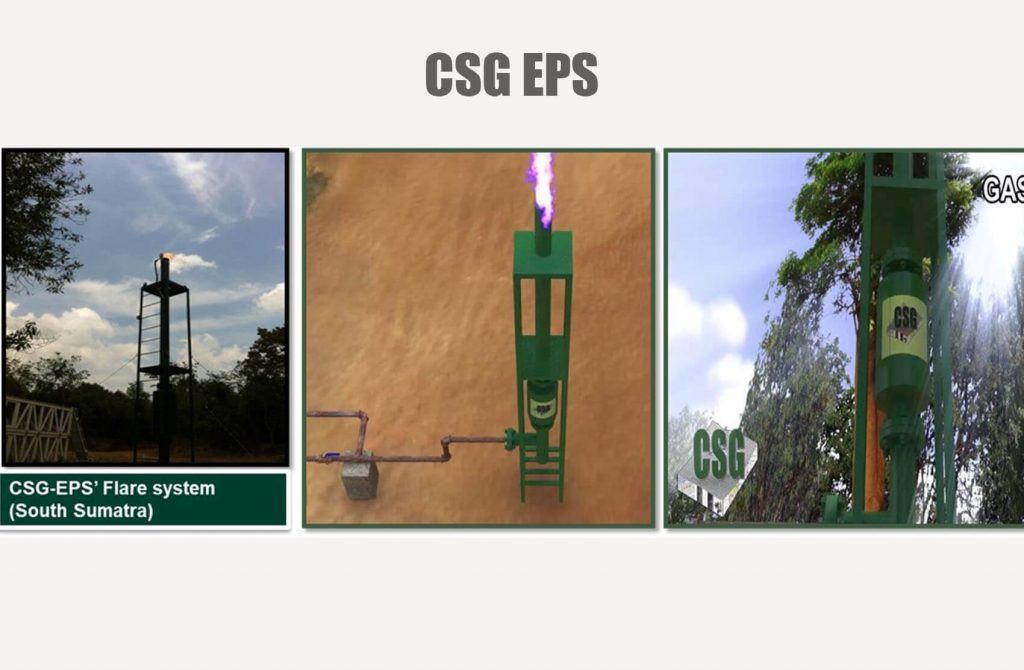

GAS FLARE SYSTEMS:

Produced gas from the gas wells is burnt and flared during production. A number of flare systems have been designed and built by CSG-EPS for burning the gas. Methane (CH4) is a greenhouse gas that remains in the atmosphere for approximately 9-15 years. Methane is over 20 times more effective in trapping heat in the atmosphere than carbon dioxide (CO2) over a 100-year period and is emitted from a variety of natural and human-influenced sources. For all these effects, methane gas is not allowed to release surface without burning.

We Design and Manufacture a number of different types and sizes of gas flares

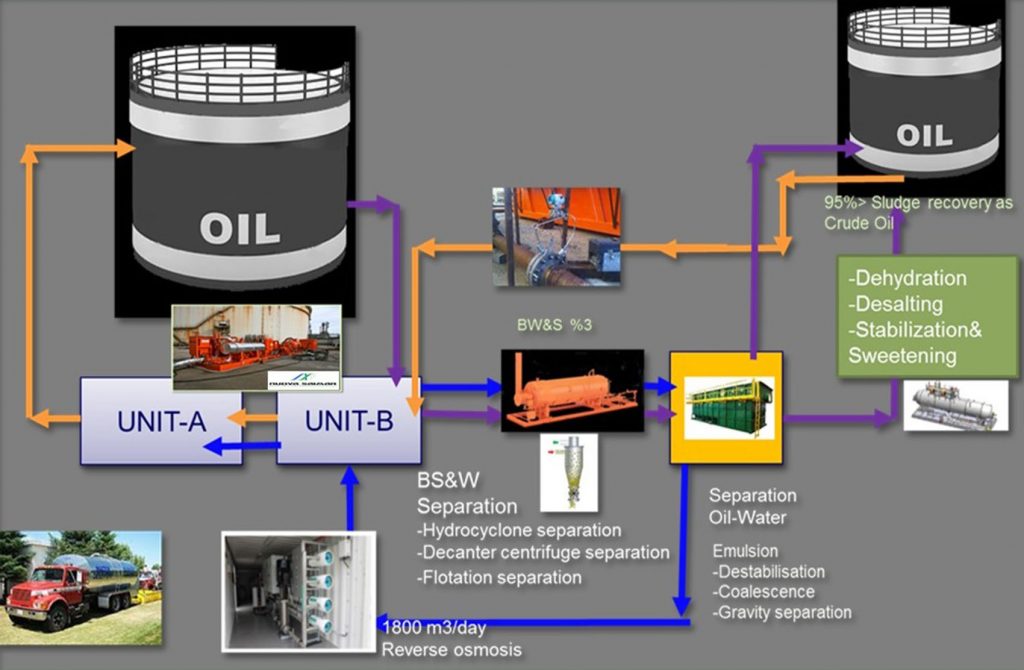

INTELLIGENT OIL SLUDGE RECOVEY SYSTEM:

CSG-EPS has been assisting clients in the oil-gas equipment, tank cleaning services more than 10 years. We are backed by a network of international associates who are service providers and major equipment manufacturers in Europe and Australia and have technical partnership support from the best establishments in our areas of operation.

CSG-EPS developed I-OSRS method which removes the sludge and bring tank to the original holding capacity. Our system, processes the sludge inside the tank, in a closed loop, in an inert atmosphere and without anybody entering the tank, then pumps back into the line and back into production. On the contrary, the processed product of a different system is treated first inside the tank, then also outside the tank. This causes hazardous emissions, a further processing of the same product and a reduction of the recovered hydrocarbon percentage.

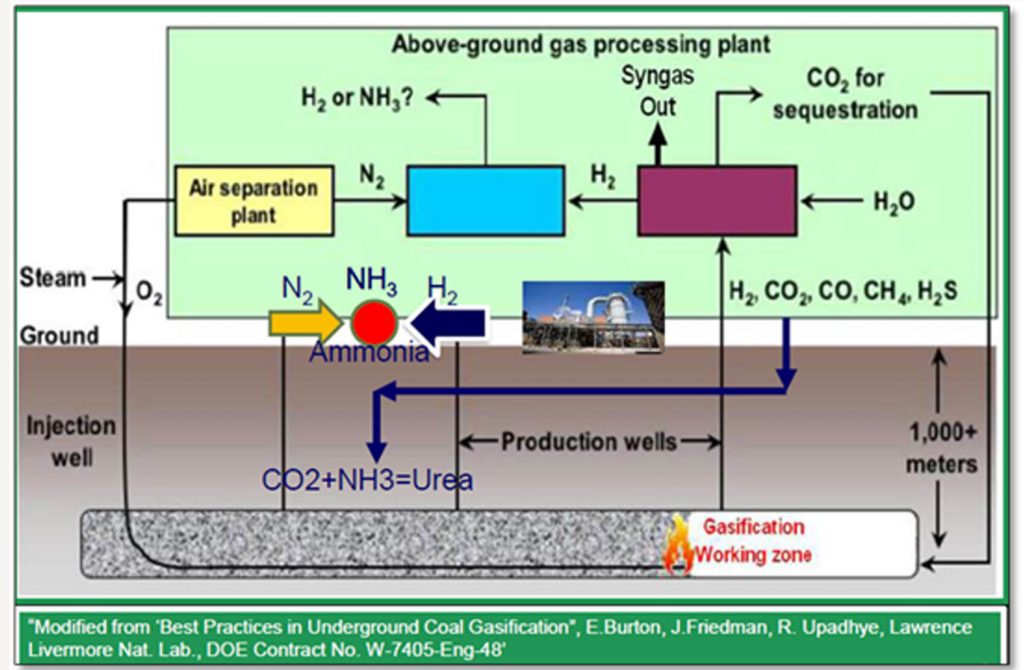

UNDERGROUND COAL GASIFICATION PROCESSING METHOD:

Gasification is a process for transforming a solid or liquid fuel, usually coal, petroleum, or biomass, into a combustible gas called synthesis gas or syngas. Syngas can be used to produce heat or generate electricity or it can be used as a feedstock for gas to liquids processes producing synthetic fuels or for a range of chemical products. Gasification is a well-developed technology and currently there are hundreds of gasification plants in operation globally including at least 160 which utilize coal and produce in excess of 50,000 MW (thermal) of syngas. (Best Practice in Underground Coal Gasification (Burton, Friedman, Upadhye, Lawrence Livermore National Lab).

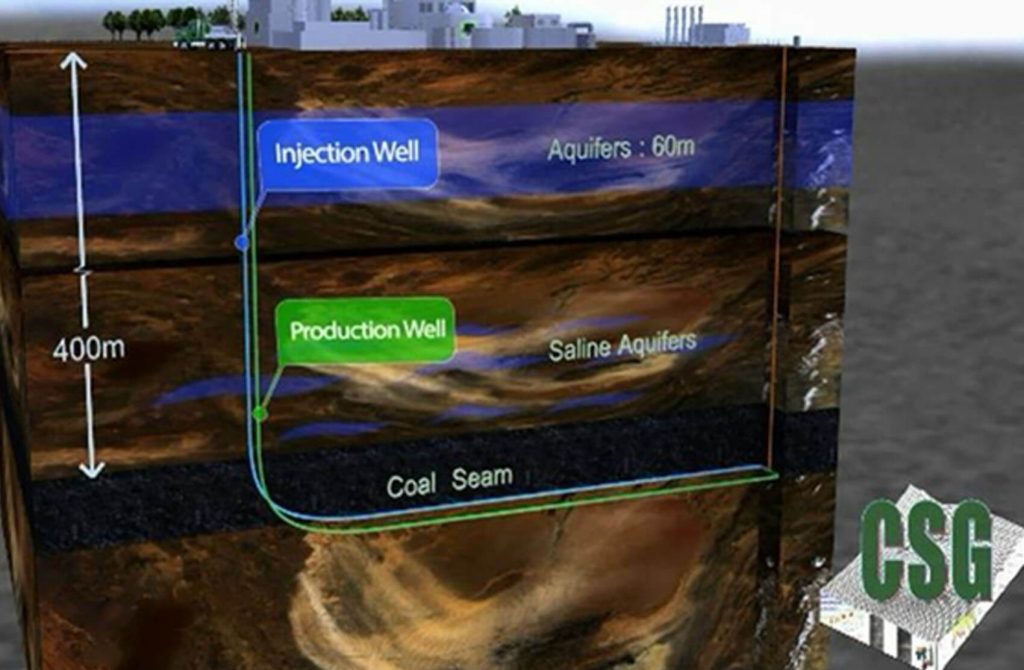

CSG-EPS has developed advanced screening, analyzing and testing methodology (GR-28-2015) for underground coal gasification and provided a number surfaces to UCG developing projects. CSG has developed its unique Gasification technology, which enables synthetic natural gas to be continuously manufactured at costs that are competitive with most alternative gas sources. CSG’s main objective is to bring affordable unconventional energy technology to Asia Pacific (especially Indonesia and Malaysia) as well as providing a simple, cost effective solution to the reduction of greenhouse gas emissions from farming and agricultural wastes.

Selection of UCG areas and coal resources is a complex process and needs to be done utmost expertise and engineering practises. The following stages are followed in UCG site assessment and plant building:

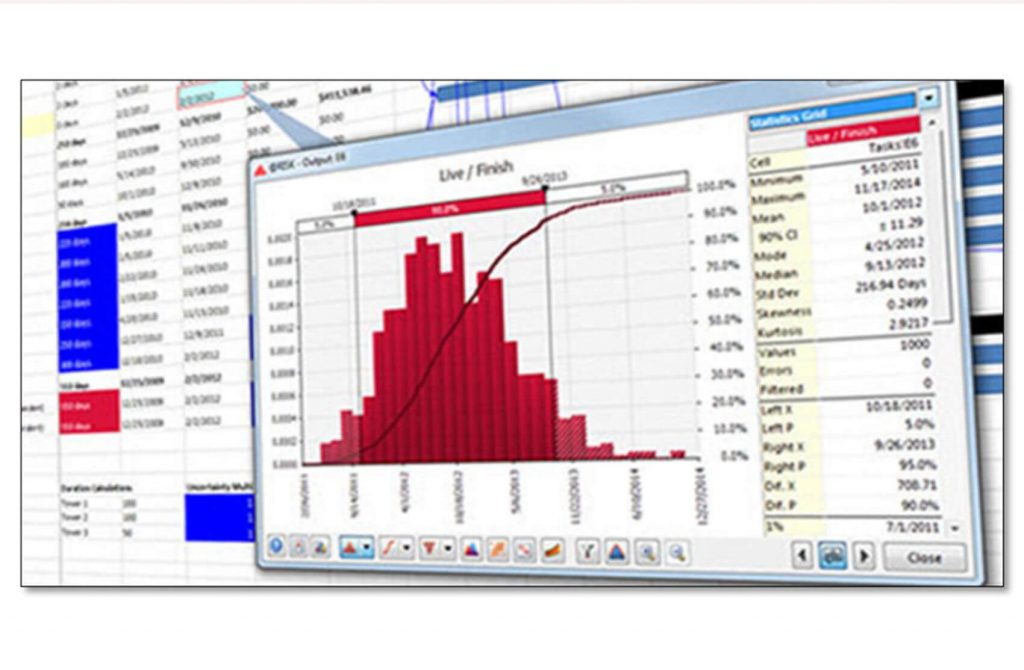

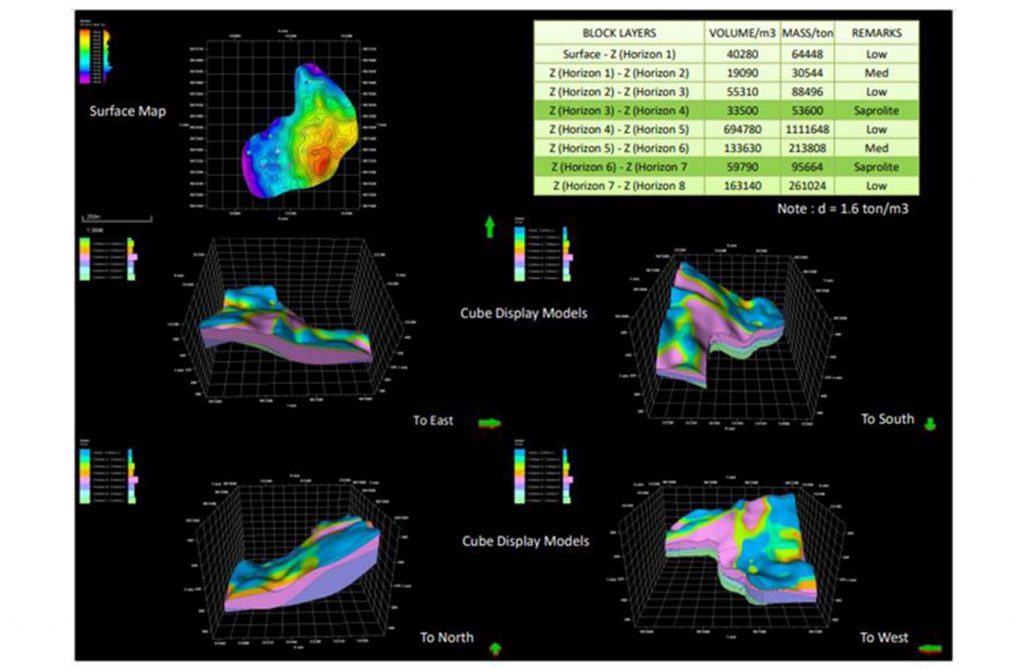

INTELLIGINET MINING RESOURCES MANAGEMENT SYSTEM:

CSG-EPS has developed intelligent system from exploration stage to development/production for mineral resources asset management. This includes, automated reporting, communication and monitoring for all activities in sampling, testing, analyzing, mapping, resource estimation, mine design, production and economics. Data management strategy plan is critical for an effective Resource Management and Prospect Evaluation, including;

Poor data capture leads to issues with data quality and integrity. The cost of fixing these problems are revealed in many ways, such as rework programs, poor decision making, failure to recognise new opportunities and wasted resources. Businesses spend too much effort managing the downstream impact of poor data collection. CSG-EPS’s Intelligent Mining resources Management System automated and simplifies all procedures and operation activities.

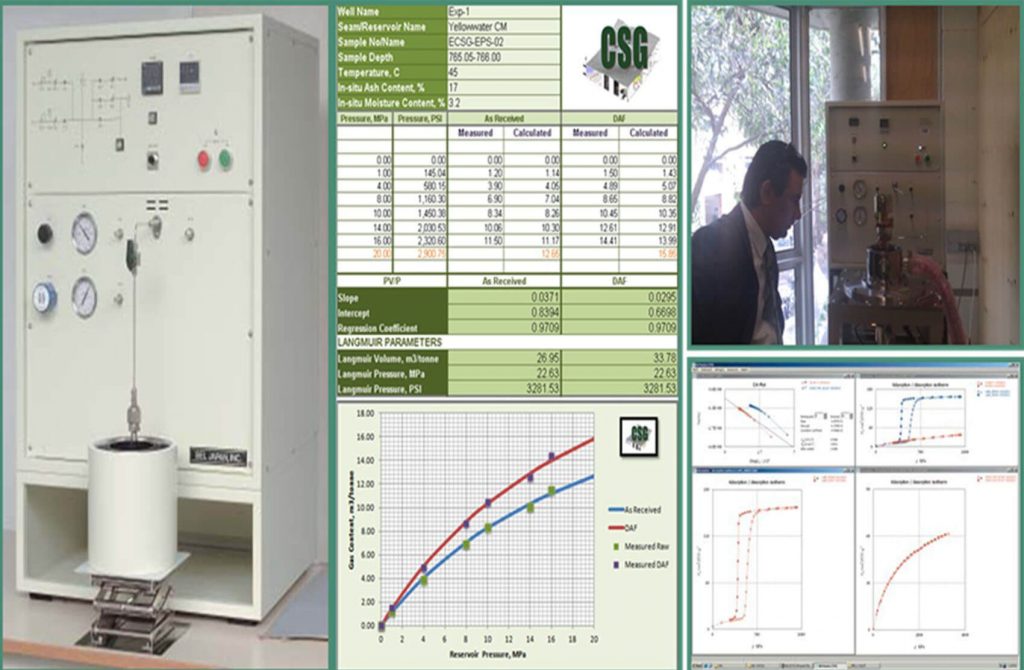

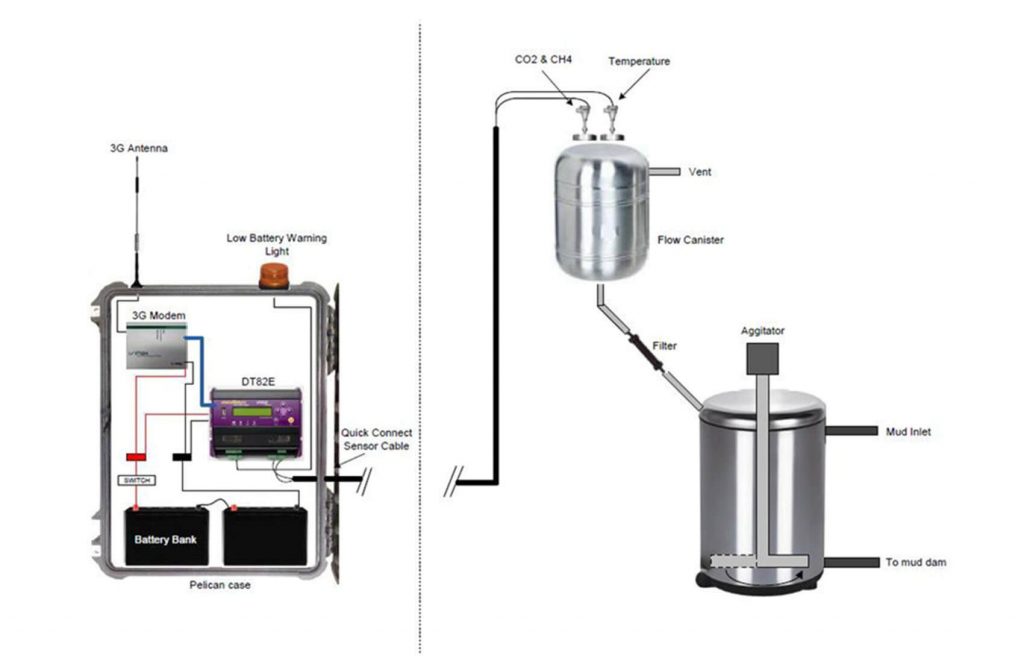

GAS TESTING SYSTEMS:

CSG Exploration & Production Services now provide fully automated continuous gas logging system for shale and coal seams in gas prospectivity operations. The system was developed by CSG-EPS for automated gas logging from the formations.

Gas desorption unit is the system that is able test a number of coal samples for gas content test. It consists of measuring cylinders, water bath, water heating system, thermometers, barometers, connection hoses, gas canisters, temperature control units, water pumps and water trough. Gas desorption should be run in temperature controlled, closed environment in order to obtain accurate results.

CSG-EPS has its own developed gas desorption testing systems for coal and shales.